- The lost performance of the stochastic is costing chip manufacturers billions in advanced process nodes

- Current process control methods are not enough to solve high volume stanza failures

- New white art document describes the design and measurement solutions to close the stochastic gap

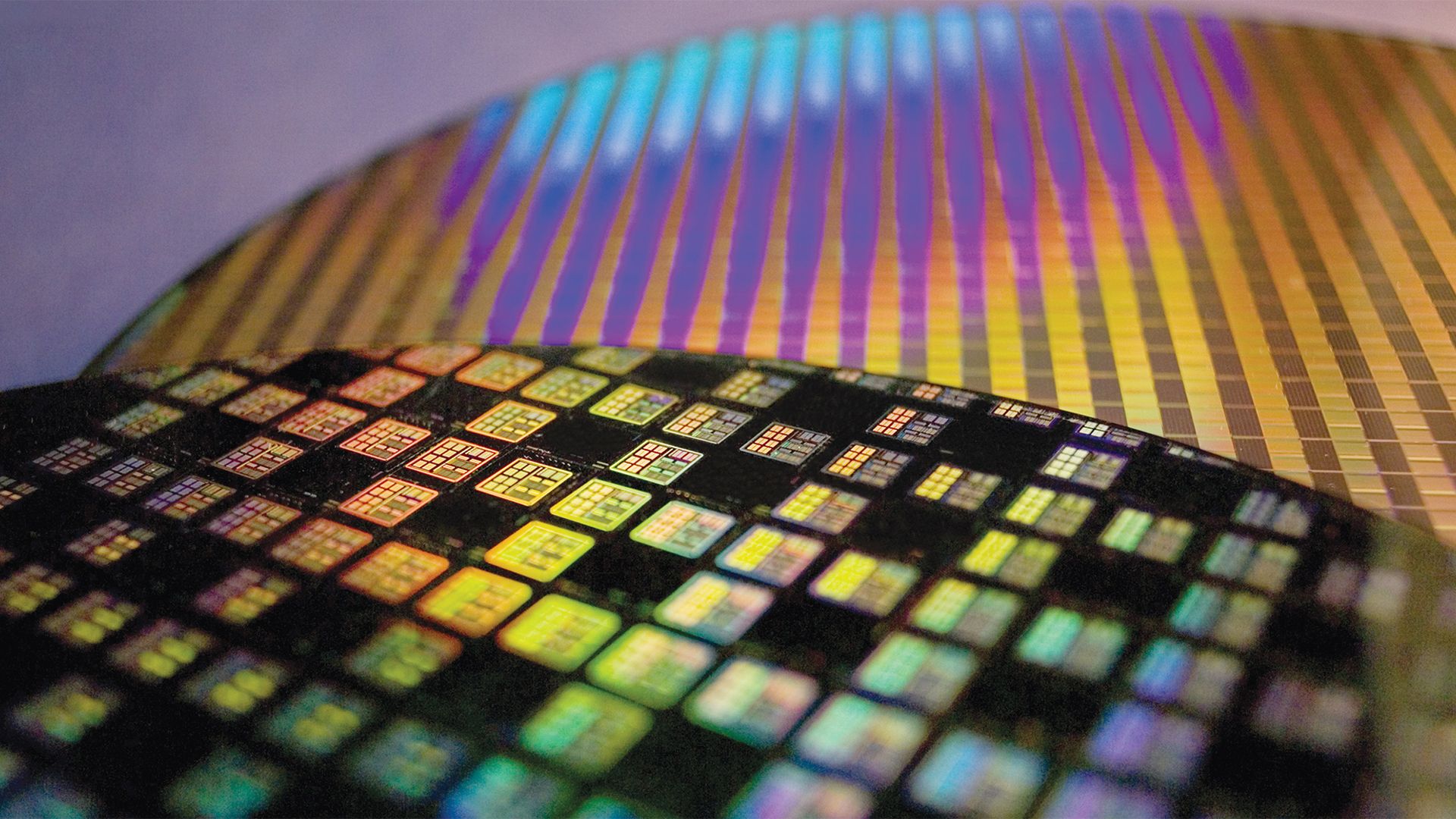

A new technical document has affirmed that the semiconductor industry is losing billions of dollars due to something that few outside the field have heard: Stochastic variability.

This form of variation of random patterns is now considered the greatest obstacle to achieving high yields in the most advanced process nodes.

The document was contributed by Fractilia based in Austin, Texas, whose CTO, Chris Mack, he said, “Stochastic variability is contributing to multimillionaire delays to introduce advanced process technology in high volume manufacturing.”

Affecting performance, performance and reliability

Mack explained that current process control strategies have not been able to address these random effects.

“Closing the stochastic gap requires completely different methodologies that device manufacturers need to validate and adopt,” Mack said.

Fractilia defines this “stochastic gap” as the difference between what can be modeled in research and what can be reliable for acceptable yields.

In the heart of this gap there is a randomly rooted in the physics of the materials, molecules and light sources used in the production of chips.

Although these effects were once insignificant, they now consume a growing part of the manufacturing errors budget.

“We have seen our customers make dense characteristics as small as 12 nanometers in research and development,” Mack said. “But when they try to move it to manufacturing, stochastic failures are affecting their ability to achieve acceptable performance, performance and reliability.”

The problem has grown together with the increase of EUV and the high EUV lithography in Na. These advances have allowed chips manufacturers to try even smaller characteristics, but they have also made them more vulnerable to stochastic defects.

Unlike conventional variability, this type cannot be eliminated with stricter controls, it must be administered with design and measurement techniques based on probability.

“The stochastic gap is a problem throughout the industry,” Mack said. “This problem can be minimized and controlled, but everything begins with a precise stochastic measurement technology.”

The technical document, which can download here, includes an analysis of the problem and proposes stochastic design, innovation of materials and controls of updated processes such as the way forward.