Swiss startup Apheros has unveiled a new way to address global demand for data processing driven by the rise of artificial intelligence (AI) and large programming languages (LLM).

The company has developed a novel metal foam that it claims could revolutionize cooling systems used in data centers.

As pressure on data centers continues to increase, cooling systems become more crucial to maintaining their optimal operation and often account for nearly 40% of their total energy consumption.

Efficient cooling solution for data centers

Data centers are increasingly tasked with managing complex AI workloads, which require specialized hardware such as GPUs and TPUs.

These components generate significant amounts of heat, requiring advanced cooling systems to prevent overheating and ensure consistent performance. Traditionally, data centers have relied on heating, ventilation, and air conditioning (HVAC) systems for cooling. However, as server density increases, these air-based systems have become insufficient.

To address these limitations, more efficient cooling methods have emerged, including immersion cooling and direct-chip cooling. Immersion cooling involves submerging servers in a dielectric liquid, while direct-chip cooling circulates coolant through cold plates attached to the chips. Both methods rely on efficient heat exchange to transfer heat from the chips to a cooling medium, which is where Apheros’ metal foams come into play.

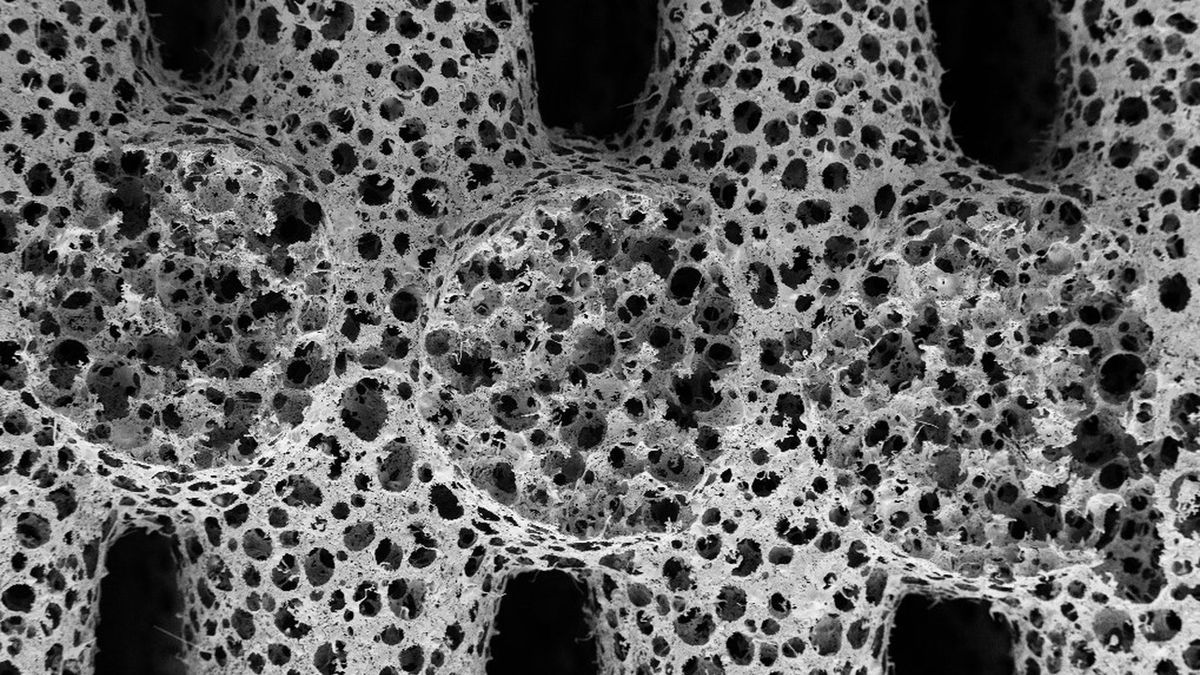

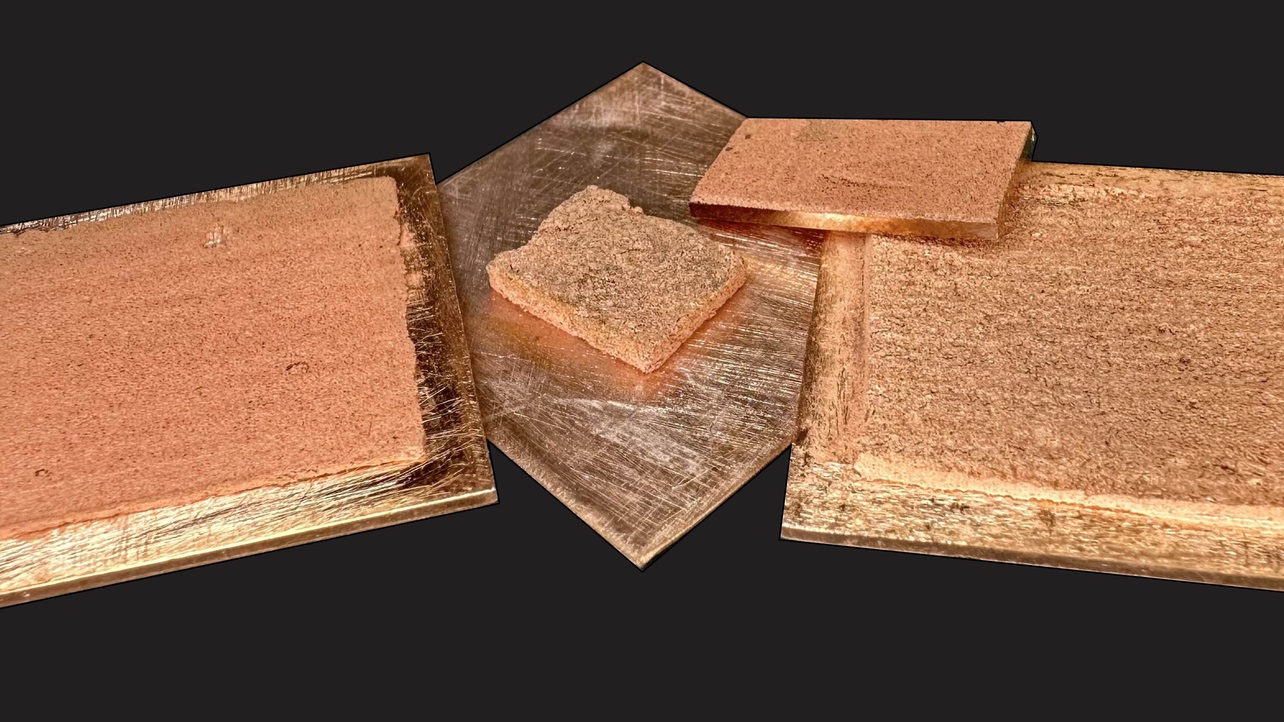

Metal foams are available in various compositions, including copper, nickel, iron and stainless steel. Their structure features completely open porosity with interconnected pores, resulting in a surface area 1000 times larger compared to traditional solutions. The foams have densities ranging from 0.9 to 2.2 g/cm3.

Apheros uses a patent-pending, easily scalable, powder-based method that operates at room temperature, which it claims results in consistent properties and high open-cell porosity, based on established food production techniques such as chocolate mousse and meringue, allowing for the creation of mechanically stable foams.

Apheros metal foams have high thermal conductivity and can provide up to 90% better heat exchange compared to traditional solutions. This enables the use of higher coolant temperatures, resulting in 10-20% energy savings in cooling systems, which not only reduces operating costs but also supports the growing need for sustainable data center operation.

The foams are optimal for passive cooling applications such as heat sinks and are suitable for single-phase cold plates and immersion cooling in data centers. There is also potential for two-phase direct-to-chip cooling. In addition, the large surface area makes the foams suitable for use as electrodes and catalysts.

Julia Carpenter, co-founder and CEO of Apheros, said: VentureBeat“This ultra-high surface area metal foam is placed directly on the chip and allows liquid to flow through it. So, in the case of on-chip cooling, it acts like a kitchen sponge with very fine porosity, where water or coolant flows through and carries away heat. This also happens in immersion cooling.”

“The increased heat transfer efficiency of Apheros foams translates directly into energy saving benefits as it allows data centers to utilize higher coolant temperatures. This is crucial as it enables heat exchange with the outside air without using water-intensive evaporation towers or energy-intensive processes such as compression.”