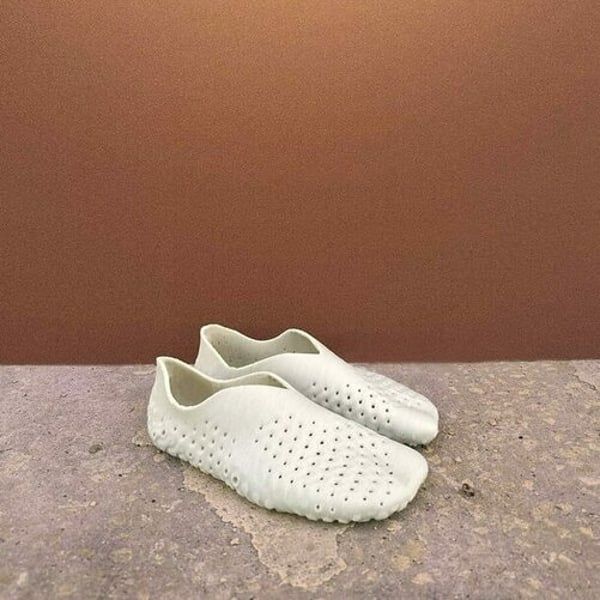

Eco-friendly footwear specialist Vivobarefoot has revealed what it says is a “groundbreaking collaboration” with materials science specialist Balena in a 3D printed shoe made entirely of compostable materials.

have revealed a sneaker prototype that, they said, “represents an important leap towards sustainable and personalized footwear.”

It comes after Puma learned in November that the sports giant had shown it can “successfully compost an experimental version of its classic Suede sneaker under certain tailored industrial conditions” following a two-year Re:Suede experiment. duration.

Clearly, sustainability is gaining popularity in the footwear segment and materials science is at the center of this.

The Vivobarefoot/Balena innovation has just been presented at the Biofabricate materials conference. They said the 3D printed shoe is made entirely of compostable materials.

The product, called “scan to print on floor” by the company, introduces a fully automated process in which users can scan their feet on their phones, initiating an automatic 3D printing of shoes tailored to their individual foot shape.

This makes the shoe the The world's first 3D printed and locally custom made shoe that is fully compostable.

The key to this is Balena's recyclable, bio-based and compostable thermoplastic material BioCirflex.

Vivobarefoot co-founder Asher Clark said: “The world doesn't need new shoes. We need a new system and new materials. “This future is literally at our feet and this shoe will allow us to reconnect with nature, move as nature intended and return the shoe to nature when we are done.”

The prototypes are being manufactured using a proprietary scan-to-print computational design system that, if scalable, “will allow them to make footwear on demand for individuals, not mass markets.”

Copyright © 2024 FashionNetwork.com All rights reserved.